It will take India a long time to match up to China in manufacturing: Revathi Advaithi, CEO, Flex

Revathi Advaithi, CEO of global manufacturing company Flex, talks about the India focus and what it will take for the country to become a global manufacturing hub

Revathi Advaithi, CEO, Flex

Revathi Advaithi, CEO, Flex

Revathi Advaithi was the only woman in her batch at BITS Pilani in the 1980s. People never failed to tell her she had made an unusual career choice, opting for mechanical engineering. One of her professors was sure she would faint in the workshops because there was manual work to be done under intense heat. “And then, two boys fainted in front of me. But I didn’t. I never fainted in my four years there,” Advaithi recollects. Even as she moved to the US, started working in the manufacturing sector and rose up the career ladder, it was “apparent that women don’t end up in manufacturing”. But, she says, it never bothered her. “It required me to work differently, work harder. But I loved what I was doing. I enjoyed being in a factory.”

At 54, Advaithi is the CEO of Flex, a Nasdaq-listed, Singapore-domiciled American manufacturing company that has over 170,000 employees across 30 countries. With over $26 billion in revenue in the fiscal year ended March 2022 and close to $8 billion in market capitalisation, Flex is the third-largest electronics manufacturing company in the world. On July 27, the company announced its Q1FY23 results, registering $7.3 billion in net sales, led by China, Mexico and the US. India, Advaithi says, is among the top 10 markets for Flex.

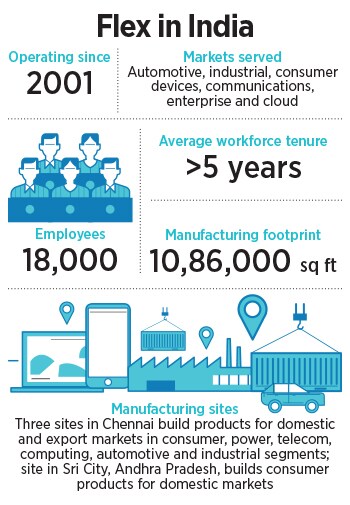

The company has been present in India since 2001, has over 18,000 employees, about 10,86,000 sq ft of manufacturing footprint, and helps make smartphones, laptops, servers, automotives, and consumer electronics products, among other things.

Advaithi, who is based in San Jose, US, has earlier held leadership positions in power management company Eaton and technology company Honeywell. In a freewheeling interaction with Forbes India during her visit to Chennai at the end of June, she talks about where India stands as a priority for Flex, what it will take for the country to match up to China in terms of size and scale of manufacturing, impact of inflation, and timeless leadership lessons she learnt while working as a shop-floor supervisor in Oklahoma. Edited excerpts:

Q. Does your India visit have any particular business agenda?

Q. Why did you decide on a career in manufacturing?

Q. Why did you decide on a career in manufacturing?