Meghalaya's Star Cement is the largest player in Northeast. Can it shine pan India?

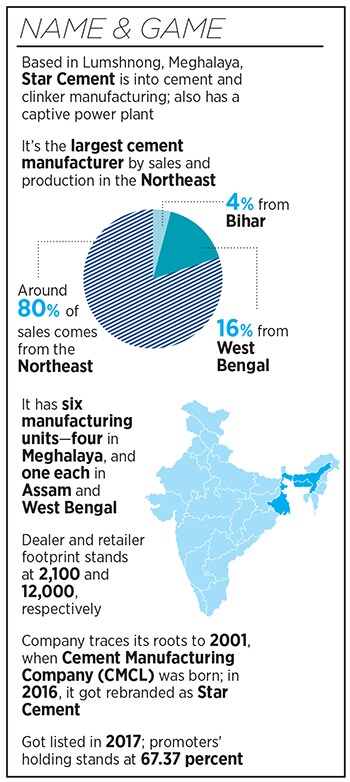

With six manufacturing units, 2,100 dealers and 12,000 retailers in its network, Star Cement is the largest player by sales and production in the region with 80 percent sales coming from the region. Now it wants to spread across India

Rajendra Chamaria, Vice Chairman and MD, Star Cement Ltd.

Image: Amit Verma

Rajendra Chamaria, Vice Chairman and MD, Star Cement Ltd.

Image: Amit Verma

New Delhi, December 1996. It was a body blow for Rajendra Chamaria. In December, the Supreme Court imposed a blanket ban on cutting of trees in Northeast India. Chamaria, whose forefathers migrated from Rajasthan to Assam over one-and-a-half century ago, had built a sizeable timber empire in the Northeast. After a partition in the family business, Chamaria’s father relocated to a remote corner of Arunachal Pradesh in 1971, and started rebuilding the timber business. “There was no electricity, no school, and zero infrastructure,” recalls Chamaria, who completed his graduation from Assam in 1979 and joined his father. “He started from zero,” he underlines.

Seventeen years later, in 1996, Chamaria was almost back to zero. His business came to a screeching halt. The judicial verdict, however, had one more component. It restricted existing players from disposing their stock, raw materials and finished products. “We were down in the dumps,” he recounts. In fact, it was towards the beginning of 1992, when Chamaria’s star started aligning in a chaotic manner. On February 5, he got abducted by the ultras from his residence in Banderdewa, Arunachal Pradesh. After a week of hectic rescue operations by the state government, the entrepreneur was freed. “Whatever years I have lived since then are a bonus,” beams the 64-year-old on a Zoom call. The incident shook the family to the core, Chamaria relocated to Delhi, and started remotely running the business operations. “In 1996, I realised the peril of the business being heavily dependent on timber,” he rues.

In fact, it was during the late 80s when Chamaria inadvertently started diversifying the business. In 1988, he set up a manufacturing unit for concrete sleepers when he won a government contract. Two years later, in 1990, he rolled out a tiny cement unit in Jaipur, Rajasthan. The project—Chamaria calls it a pilot—was more of an experiment to test the waters. In 1995, the diversification juggernaut gathered steam when he made heavy investment and set up a cement plant in Himachal Pradesh. A year later, when the timber business got massively hit, Chamaria thought his cement ventures would cushion the impact.

In fact, it was during the late 80s when Chamaria inadvertently started diversifying the business. In 1988, he set up a manufacturing unit for concrete sleepers when he won a government contract. Two years later, in 1990, he rolled out a tiny cement unit in Jaipur, Rajasthan. The project—Chamaria calls it a pilot—was more of an experiment to test the waters. In 1995, the diversification juggernaut gathered steam when he made heavy investment and set up a cement plant in Himachal Pradesh. A year later, when the timber business got massively hit, Chamaria thought his cement ventures would cushion the impact.

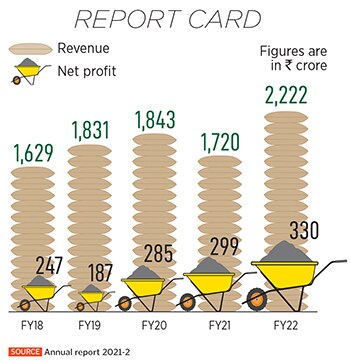

The company indeed has grown at a superfast pace. From a clinker and cement capacity of 0.3 million metric tonnes and 0.4 million metric tonnes, respectively, in FY05, the numbers leapfrogged to 2.8 MTPA (million tonnes per annum) and 5.7 MTPA in FY21. With over 23 percent market share, Star happens to be the biggest cement player in terms of volume and capacity in the Northeast. It has six manufacturing units—four in Meghalaya, and one each in Assam and West Bengal. The scale has been matched by growth of revenue. From ₹1,629 crore in FY18, it has surged to ₹2,222 crore in FY22. Net profit, however, slipped a tad lower from ₹330 crore to ₹247 crore.

The company indeed has grown at a superfast pace. From a clinker and cement capacity of 0.3 million metric tonnes and 0.4 million metric tonnes, respectively, in FY05, the numbers leapfrogged to 2.8 MTPA (million tonnes per annum) and 5.7 MTPA in FY21. With over 23 percent market share, Star happens to be the biggest cement player in terms of volume and capacity in the Northeast. It has six manufacturing units—four in Meghalaya, and one each in Assam and West Bengal. The scale has been matched by growth of revenue. From ₹1,629 crore in FY18, it has surged to ₹2,222 crore in FY22. Net profit, however, slipped a tad lower from ₹330 crore to ₹247 crore.  Star Cement’s strong performance, point out analysts, has a lot to do with its dominant position in the Northeastern markets. “A strong brand presence across the Northeastern region enables the group to enjoy premium pricing compared to some of the other cement companies located in the region,” underlines ICRA in its ratings report last December. Availability of tax benefits and GST refunds further strengthen the operating profile of the consolidated entity and have resulted in cost savings, the note added.

Star Cement’s strong performance, point out analysts, has a lot to do with its dominant position in the Northeastern markets. “A strong brand presence across the Northeastern region enables the group to enjoy premium pricing compared to some of the other cement companies located in the region,” underlines ICRA in its ratings report last December. Availability of tax benefits and GST refunds further strengthen the operating profile of the consolidated entity and have resulted in cost savings, the note added.