Log9: Holding the key to India's self-reliance in critical areas of the EV sector

The Bengaluru-headquartered company indigenously manufactures cells that make up the battery packs that go into electric vehicles. It also attacks two technical problems inherent to any of the current cells and batteries in the market

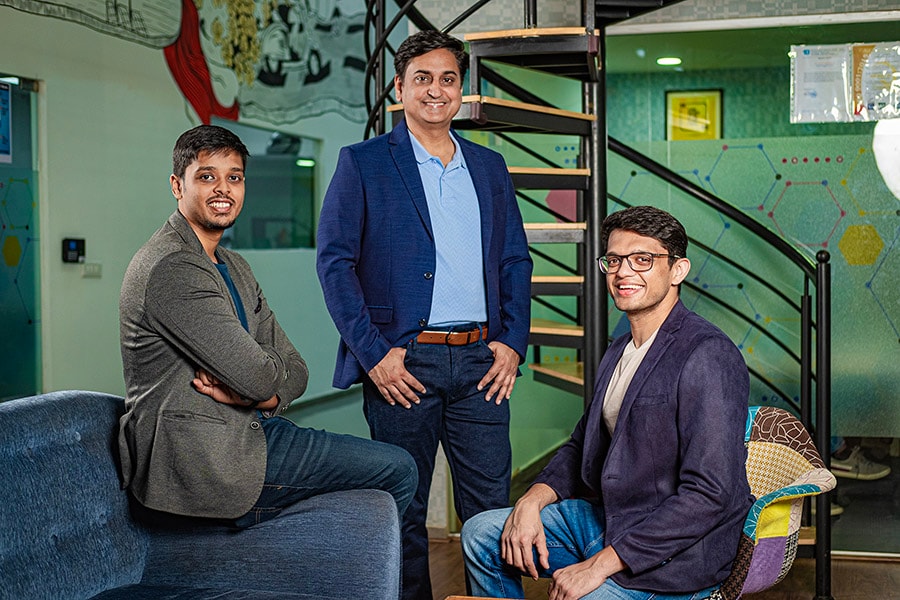

(From left) Karthik Hajela, Pankaj Sharma and Akshay Singhal, Co-founders, Log9

(From left) Karthik Hajela, Pankaj Sharma and Akshay Singhal, Co-founders, Log9

As with many other hardware components and products, when it comes to cells that make up the battery packs that go into electric vehicles (EV), China is the world’s biggest supplier. More importantly, India has zero commercial capacity, which means the country imports these cells.

At Log9, Akshay Singhal, Kartik Hajela and Pankaj Sharma are changing that one cell at a time. The task is massive, but it holds the key to India’s self-reliance in critical areas of the EV sector.

“The biggest challenge is that it's never been done in India, before,” says Hemant Charaya, senior vice president for battery cell technology at Log9, who leads the company’s cell chemistry and engineering team. And even in the rest of the world, there is a scarcity of the talent everywhere, he says.

And while India has millions in the IT services industry, when it comes to developing a lithium-ion cell, setting up the necessary R&D and then a factory to make them, there wasn’t an existing talent pool for Log9 to dip into.

“It's very difficult to find somebody who has worked on these kind of lines… who has worked on building these kind of cells,” Charaya says. Today, Log9’s cell team is upwards of 40 people and it has been painstakingly put together “organically” over the last three years. “The good part is, they stuck around,” he adds.