Green hydrogen can help India meet its net-zero ambitions. How long before a real impact is seen?

The carbon-free gas has the potential to help India achieve its net zero ambitions and the government is putting its might behind it with its National Green Hydrogen Mission. But how long before we see large-scale adoption?

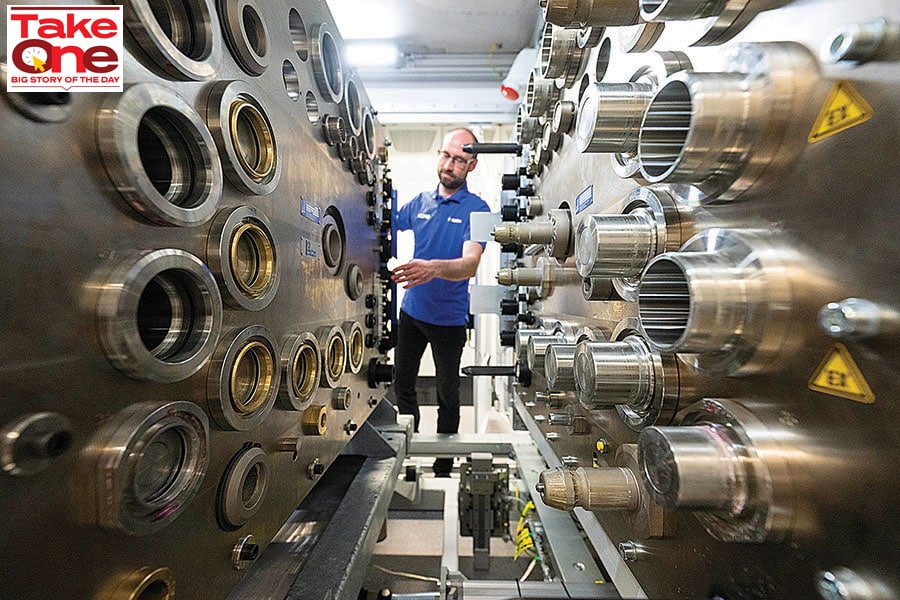

An employee at a German plant prepares a test bench for end-of-line testing of a fuel cell drive system for generating electricity from hydrogen in vehicles. The so-called fuel cell power module (FCPM) is used primarily in commercial vehicles

Image: Marijan Murat / Picture Alliance via Getty Images

An employee at a German plant prepares a test bench for end-of-line testing of a fuel cell drive system for generating electricity from hydrogen in vehicles. The so-called fuel cell power module (FCPM) is used primarily in commercial vehicles

Image: Marijan Murat / Picture Alliance via Getty Images

Just off Bhuvanappa Layout in Bengaluru, a little known hydrogen startup with just 20 employees is attracting attention from large corporations.

Ossus Biorenewables has devised a technique that uses proprietary bioreactors to convert the organic carbon content in industrial effluents to so-called “green” hydrogen—a light, colourless gas that doesn’t produce carbon dioxide when burnt.

A large steel manufacturer was the first customer. Half a kilometre away from its plant, where the steel maker’s wastewater was otherwise treated and disposed, Ossus has installed its cylindrical-shaped bioreactors that draw out the organic matter from the effluents and convert it to green hydrogen. It has the twin benefit of eliminating the need to compress, store and transport hydrogen—seen as a stumbling block—besides recycling the wastewater.

Ossus currently produces 30 kg of green hydrogen per day for the steel maker from 6,000 litres of their effluent, at a fraction of the cost it paid to Linde, an Irish supplier of green hydrogen.

Ossus has since been working with companies across industries from oil refineries to cement makers, sugar mills to textile factories, as well as food and beverage. Nikhil Kamath’s Gruhas and Rainmatter Climate are investors having put in $2.4 million in Pre-Series A funding in April.

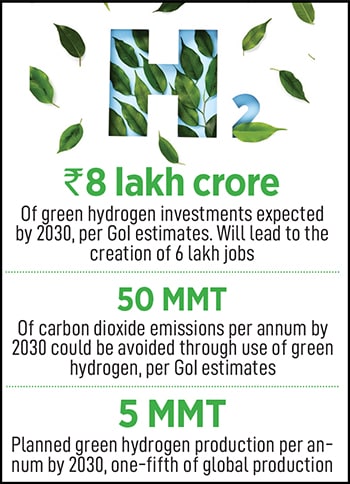

Interest in the production of green hydrogen has grown, especially over the last year, since the government announced the National Green Hydrogen Mission in Budget 2022 with an allocation of ₹19,700 crore in order to produce five million metric tonnes of the gas by 2030. Companies big and small have been making investments to set up plants, produce new technologies and pilot projects.

Interest in the production of green hydrogen has grown, especially over the last year, since the government announced the National Green Hydrogen Mission in Budget 2022 with an allocation of ₹19,700 crore in order to produce five million metric tonnes of the gas by 2030. Companies big and small have been making investments to set up plants, produce new technologies and pilot projects.