Why the Kapurs of Steelbird believe family businesses are like helmets

Started in 1964, Steelbird survived a bumpy ride and emerged as one of the top helmet makers in India with a wide global footprint. Now the Kapurs have buckled up for a bigger and diversified play

Subhash Kapur (sitted), Chairman, Steelbird Group, Rajeev Kapur(left), MD, Steelbird Group and Kashish Kapur, Director, Steelbird Group

Image: Madhu Kapparath

Subhash Kapur (sitted), Chairman, Steelbird Group, Rajeev Kapur(left), MD, Steelbird Group and Kashish Kapur, Director, Steelbird Group

Image: Madhu Kapparath

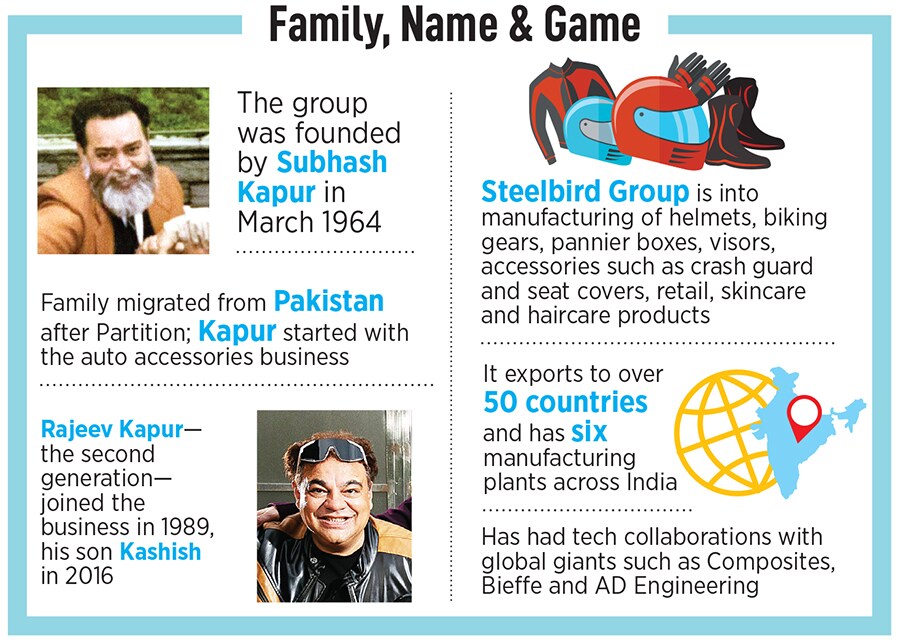

1996, Italy. A father and son were eagerly looking forward to their first global contract. The duo was about to meet the CEO of an Italian helmet major, which entered into a tech tie-up with the Kapurs two years ago and was eager to take supplies from the Indian partner. “They would be pleasantly surprised to see the quality,” Subhash Kapur said to himself. It was a big moment for Kapur, whose father came to India after Partition. From being one of the richest families in Pakistan with a chain of gold stores and acres of land under their belt, the Kapurs started from scratch in India. Over the next few years, they tried a couple of small ventures which could not be scaled— such as making sacks for salt players.

In 1964, Kapur started Steelbird Group by making auto components and then dabbled into the business of helmets over the next few years. His son Rajeev joined straight after finishing high school in 1989. The reason was not a lack of interest in studies. “I was too impatient,” recalls the managing director of Steelbird, one of the top helmet makers in India. He justifies his haste. “Three years of graduation, and then a few more years of MBA… didn’t want to wait for so long,” recounts the second-gen entrepreneur who joined the venture when he was 20.

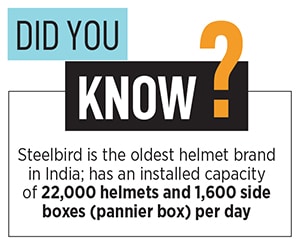

Back then, in 1989, Steelbird used to make around 100 helmets every day. Branded helmet was a hyper-niche market in India, and the Kapurs didn’t play price warrior. “Hamari helmet pehen ke koi marna nahin chahiye (nobody should die wearing our helmet),” was the senior Kapur’s advice to his son, who was frustrated to see a flourishing sea of fake helmets across the country. The message from the patriarch was clear: Don’t cut corners. “Helmet might be a business, but it’s a safety device,” he underlined.

The young one soaked in the message, and started working on a bigger game plan. In 1994, he managed to stitch a technical collaboration with Bieffe, which was then the world’s leading helmet manufacturer. The idea was not to sell Italian helmets in India but to supply helmets to them. For two years, Steelbird worked on making a helmet which could meet the global standards on all parameters.

The young one soaked in the message, and started working on a bigger game plan. In 1994, he managed to stitch a technical collaboration with Bieffe, which was then the world’s leading helmet manufacturer. The idea was not to sell Italian helmets in India but to supply helmets to them. For two years, Steelbird worked on making a helmet which could meet the global standards on all parameters.