Explained: What is the digital twin technology and how does it work

From health care to manufacturing, the technology will help rehearse for the future and improve lives. Experts, however, raise concerns about privacy and security as it involves collecting huge chunks of data

Image: Shutterstock

Image: Shutterstock

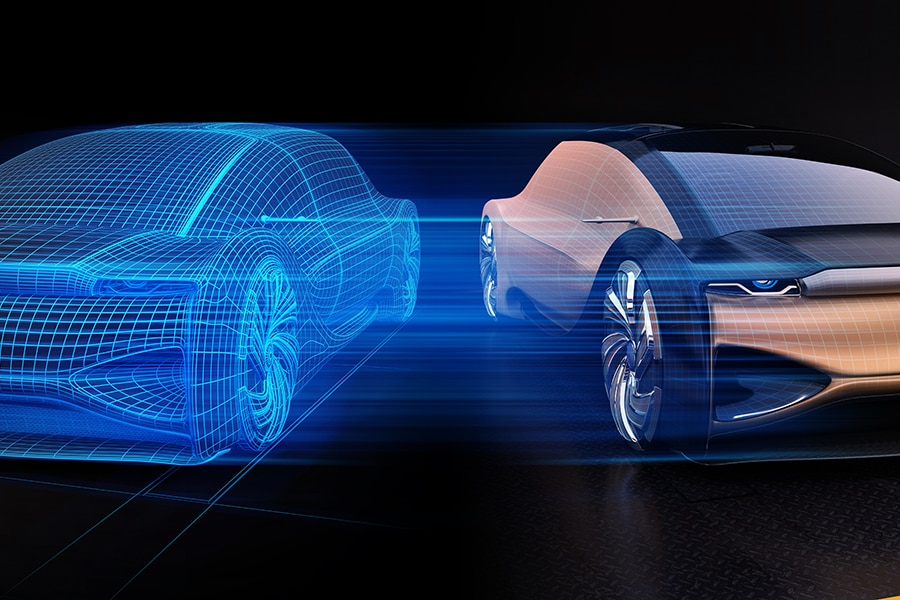

Digital twin is a virtual copy of physical products, processes or systems. The virtual model is designed in such a way that it accurately reflects the physical object—both of them are interconnected via exchange of data in real time. The Digital twin technology will be used to simulate, predict and improve real-world activities. It will transform homes, workplaces, communities, and even manufacturing and health care in the coming years. According to findings from Tata Consultancy Services (TCS) futurists in TCS Digital Twindex report, digital twins will become commonplace across business and society by 2035.

What are the advantages and use cases?

The advantage of digital twins is their ability to use data to model future scenarios. This capability has proven crucial in industries such as manufacturing, where digital twins can anticipate machine failures and optimise maintenance schedules, reducing downtime and costs. TCS experts predict that these benefits will be democratised across many industries in the coming years like real-time health care and efficient energy management as the two use-cases that will most benefit human lives.

In health care, digital twins of the human body can help ensure medical procedures are rehearsed and run smoothly, and enable personalised treatment. According to experts, a digital twin of the full human body is at least 10 years away, given the complexity, variations and likely regulatory requirements.

NASA was one of the first organisations to deploy this technology for space exploration missions. The term ‘digital twin’ is credited to Dr Michael Grieves, who is reported to have coined it in 2002. Digital twins use installed sensors to gather real-time data, bridging the gap between the physical and digital worlds. Either locally decentralised storage is used for the collected data, or central cloud storage is used. Following that, the data is assessed and simulated using a virtual copy of the assets. The simulation's output is received, and the settings are then applied to actual assets. The performance of physical assets is optimised thanks to the integration of data into both real and virtual representations. Industry applications for digital twins include industrial, automotive, construction, health care, and more. Digital twins are the next big thing in the Fourth Industrial Revolution for the development of new products and processes.

How will businesses benefit from this technology?

The capability to rehearse the future will be key for businesses who must navigate an increasing number of challenges in the coming years. The progress of digital twins allows us to envision a world in which the testing of new technologies happens entirely in cyberspace, explains Frank Diana, principal futurist at TCS. “In the coming years, successful businesses will be those that have the foresight and agility to treat their organisations as modular entities where capabilities can be leveraged based on need. Scenario-planning from digital twins will be essential to achieve these capabilities, and in ensuring a responsible and sustainable approach to business of the future.”