Eeki Foods: Growing more food using less

Abhay Singh and Amit Kumar of Eeki Foods are growing staple vegetables using technology that is not just climate resilient and climate saving, but also reduces growing costs

Abhay Singh (left) and Amit Kumar of Eeki Foods

Image: Madhu Kapparath

Abhay Singh (left) and Amit Kumar of Eeki Foods

Image: Madhu Kapparath

When IITians Abhay Singh and Amit Kumar found they were hopping from one job to another every year or so, it led to some introspection. It wasn’t that they didn’t enjoy what they did. The IIT-Bombay graduates had worked in robotics and automation since their college days and continued doing that in their work life. It also wasn’t that the jobs were not lucrative. And yet, there was something that didn’t quite work.

“We were always happy building stuff, but despite that, we were quitting our jobs every 12 months, and the idea was we don’t want to do that,” says Singh. Trying to understand why they were restless, the two concluded that they were working on jobs or projects that were temporary in nature whereas, “we both wanted to build something that would last for decades, if not centuries. That is the core, that feeling was missing”, he adds.

In October 2017, stepping back, the two friends spent a few months trying to figure out what they really wanted to do and also “understand life in general”. Which involved studying everything, from philosophy to political science, “everything we had never read before, to understand how the world works”.

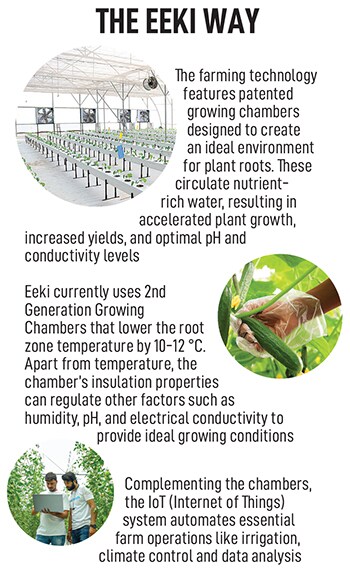

The two were in different cities—Kumar was in Delhi while Singh was at home in Rajasthan—and they exchanged notes until in early 2018 they zeroed in on land, water and food as focus areas. “We realised that arable soil is not going to increase over time while the population will. And then there was the impending climate change, so we have to figure out ways to grow more food using less [in terms of] resources,” says Singh.

Neither of them had a great passion for agriculture, so it wasn’t a passion problem they were looking to solve but a “necessary problem that has to be solved”, says Singh. Over the remaining months of 2018, they tried everything from traditional farming to hydroponics to understand what was required to shift the needle.

The challenge with hydroponics, they realised, was that it was mainly used to grow greens and exotic vegetables, and the cost of growing was high. “It was nearly ₹100-200 a kilo and in moderate climates, ₹20-30 a kilo,” says Singh, adding that even that was too high for wholesale. “We understood that you have to be able to grow more in a lesser area, but at the same time do that at a lower price. That’s the only way you can make a change possible.”

The challenge with hydroponics, they realised, was that it was mainly used to grow greens and exotic vegetables, and the cost of growing was high. “It was nearly ₹100-200 a kilo and in moderate climates, ₹20-30 a kilo,” says Singh, adding that even that was too high for wholesale. “We understood that you have to be able to grow more in a lesser area, but at the same time do that at a lower price. That’s the only way you can make a change possible.”

It was also during Covid, between the two waves, in February 2021, that angel investor Rajesh Sawhney, founder and CEO of GSF Accelerator, drove down from Delhi to Kota for two days and quickly, in March, wrote them a cheque for about $150,000 through GSF. For Sawhney, hydroponics, as it existed back then, didn’t appear to be a scalable business model, but when he got there, he understood the “vision and the potential of their technology”, he says, also pointing to their business model that has three components to it. “One is the bioengineering that they do to make beautiful vegetables; the second is the whole water conservation, it’s a very, very water-efficient system and water is circulated back. And the third unique component of their business model is that they don’t take any energy from the grid, but make their own energy through solar. That is the vision of agriculture that I immediately related to, that is not only organic, but also self-sustaining.”

It was also during Covid, between the two waves, in February 2021, that angel investor Rajesh Sawhney, founder and CEO of GSF Accelerator, drove down from Delhi to Kota for two days and quickly, in March, wrote them a cheque for about $150,000 through GSF. For Sawhney, hydroponics, as it existed back then, didn’t appear to be a scalable business model, but when he got there, he understood the “vision and the potential of their technology”, he says, also pointing to their business model that has three components to it. “One is the bioengineering that they do to make beautiful vegetables; the second is the whole water conservation, it’s a very, very water-efficient system and water is circulated back. And the third unique component of their business model is that they don’t take any energy from the grid, but make their own energy through solar. That is the vision of agriculture that I immediately related to, that is not only organic, but also self-sustaining.”