Banyan Nation: Climate warriors chipping away at India's plastic problem

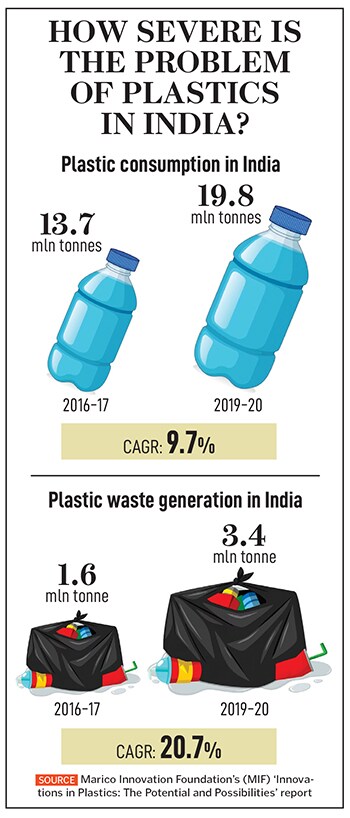

Of the 3.4 million tonne waste that the country generates, only 30 percent is recycled—the rest finds its way to landfills. Banyan Nation's HDPE plastic conversion process is bridging the gap in the recycling ecosystem of India

Mani Vajipeyajula, co-founder and CEO (right), and Raj Madangopal, co-founder and COO of Banyan Nation

Image: Madhu Kapparath

Mani Vajipeyajula, co-founder and CEO (right), and Raj Madangopal, co-founder and COO of Banyan Nation

Image: Madhu Kapparath

Please put these on as a safety measure,” said one of the employees as she handed me a pair of black boots, a helmet and a mask.

“Why do I need to wear these to go see a recycling plant?” I asked.

“There will be plastic all around, so you never know what could hit you, literally,” she replied.

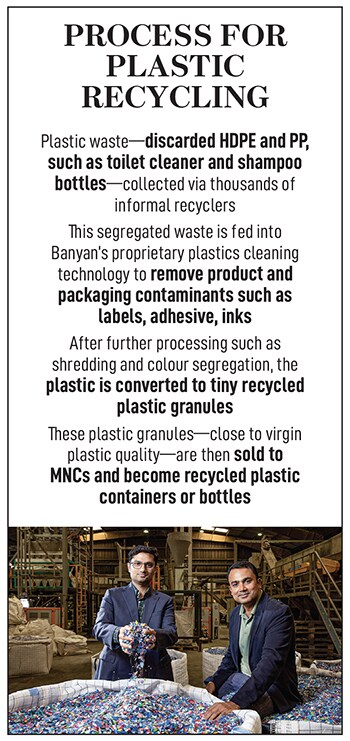

She was right. The complexity of what goes on inside a recycling unit is unimaginable: From tonnes of waste being fed into gigantic cleaning machines, colourful clean plastic shreds looking like confetti being poured out, and finally those granules being put through intensive testing.

This end-to-end model is part of the work being done at the Hyderabad-based Banyan Nation, which was founded by Mani Vajipeyajula and Raj Madangopal in 2014. The company is a vertically integrated plastic recycling company that helps brands use recycled plastics instead of virgin plastics in mainstream products and packaging, while leveraging mobile technology to map, integrate and train thousands of local kabadiwalas or informal recyclers for collection of plastics waste.

Banyan Nation collects more than 1,000 tonne of plastic waste per month, and converts them into granules that are reusable, thereby creating a circular economy.

Banyan Nation collects more than 1,000 tonne of plastic waste per month, and converts them into granules that are reusable, thereby creating a circular economy. The duo had no clear business model back then. Vajipeyajula recalls his early pitches to investors, “Raj and I were well trained in solving complex engineering problems and we wanted to apply our skills to tackle the problem of plastics pollution in India.” Investors thought both were crazy.

The duo had no clear business model back then. Vajipeyajula recalls his early pitches to investors, “Raj and I were well trained in solving complex engineering problems and we wanted to apply our skills to tackle the problem of plastics pollution in India.” Investors thought both were crazy.  The larger issue, though, points out Madangopal, “is not that of creating the right technology, but instead a mindset problem of stakeholders across the board—from the masses, to the government and corporates—that recycled plastics are somehow inferior to virgin plastics and they have to be cheaper as well”.

The larger issue, though, points out Madangopal, “is not that of creating the right technology, but instead a mindset problem of stakeholders across the board—from the masses, to the government and corporates—that recycled plastics are somehow inferior to virgin plastics and they have to be cheaper as well”.