Inside James Dyson's secretive laboratory

James Dyson has built one of the world's most innovative companies by wooing young, talented engineers to the picturesque English countryside and giving them the freedom to fail—hundreds of times. His build-a-better-mousetrap approach has made him one of Britain's richest men and revolutionised products ranging from vacuum cleaners to hair dryers. Next up? Better batteries

Dressed in a blue polka-dot oxford and striped Reebok sneakers, James Dyson abruptly veers off a paved path that cuts through his company’s 15-acre compound. The beanpole-thin 69-year-old billionaire pushes his way into some shrubbery and presses his nose right up to the reflective glass that encases his new, top-secret laboratory, a sleek two-storey cube that looks like it was beamed directly from Santa Clara to the Cotswolds. To his delight, he can’t make out what his engineers are doing inside. “I hope they are working,” he says, chuckling.

In reality, it’s move-in day at this brand-new $200-million-plus research facility, and on the other side of the glass, dozens of young engineers are unpacking their gear and settling into their quarters. Their job at D9, as the building is cryptically known, is to experiment fearlessly, fail constantly and document those failures in company-issued black-and-yellow notebooks, which form the basis for still more experiments, still more failures—and also a corporate sideline in patent litigation. Very rarely this unending cycle of failure results in a revolutionary new product: The bagless vacuum cleaner (5 years, 5,127 prototypes), the 360 Eye robot (17 years, 1,000-plus prototypes) and the Supersonic hair dryer (4 years, 600 prototypes). But those successes add up: Dyson’s 58 products generated $2.4 billion in sales last year and an estimated $340 million in net profits, even after Dyson reinvested 46 percent of the company’s Ebitda in R&D, more than rivals such as Electrolux and Techtronic. Dyson owns 100 percent of the company, which is worth some $4.8 billion.

D9 is the gleaming cornerstone of Dyson’s ongoing efforts to lure engineers straight out of college to work for him at the company’s headquarters near Malmesbury, an ancient market town of 5,400 two hours west of London. The average age of his engineers is 26 (he has 3,000 worldwide and wants to hire another 3,000 by 2020), and their youth is no accident. “The enthusiasm and lack of fear is important,” Dyson says. “Not taking notice of experts and ploughing on because you believe in something is important. It’s much easier to do when you’re young.”

Dyson’s own fearlessness enables him to constantly test new products, although his perfectionism often gets in the way of releasing them. He is best known for creating the first bagless vacuum cleaner three decades ago, and his company still gets 70 percent of its sales from vacuum cleaners, many of which are now lightweight, handheld and battery-operated. But Dyson has also had hits with the Airblade hand dryer; the Dyson humidifier; and the Pure Cool Link, a fan that doubles as an air purifier. The latest wonder from his workshop is the Supersonic blow-dryer. Dyson spent $71 million (and went through 1,000 miles of human hair) developing the $400 device, which is supposed to eliminate heat damage and cut down on uncontrollable flyaways. It launched in Japan in April and comes to the US any day now.

Dyson is hoping that all those new engineers he is hiring will accelerate the company’s pace of innovation: Dyson is planning to invest hundreds of millions of dollars to develop at least 100 new products by 2020, nearly double of what it now has on the market and equivalent to the number of products introduced since its founding. “We are reinventing ourselves all the time,” Dyson says. “We’re battling against the status quo. We still feel small, agile, pioneering.”

While Dyson is mum on specifics, he reveals that many of the new products will be related to personal care or lighting. The lighting systems are the brainchild of his eldest son and heir apparent, Jake, 46, who spent two years at Dyson before leaving in 2002 to start his own business selling self-cooling LED light fixtures. “I wanted to go out and do my own thing and prove to myself I could do this,” says Jake, who returned in April, bringing his LED technology and ideas with him.

But Dyson’s biggest bet is on batteries. In his view, the current rechargeable lithium-ion (li-ion) batteries that power most of the world’s gadgets (including his own) don’t hold a charge long enough and need to be safer (they occasionally catch fire). True to his nature, rather than incrementally improve existing li-ion technology, Dyson is forging a new path: Experimenting with solid-state li-ion batteries that use ceramics. To this end, Dyson made the first acquisition in the company’s history in October 2015, spending $90 million for Sakti3, a battery startup in Ann Arbor, Michigan. And that’s just the beginning. Dyson vows to spend $1.4 billion building a battery factory and investing in R&D over the next five years, a huge gamble for a company its size. But Dyson is undeterred, claiming that soon it will be making the world’s longest-lasting, most reliable batteries, taking dead aim at the global li-ion battery market, which research firm Lux estimates at $40 billion. “Batteries are quite exciting and sexy things,” Dyson says.

The seeds of Dyson’s determination and resilience were planted on the shores of Norfolk in northeast England, where he grew up the youngest of three siblings. His father taught classics at Gresham’s, an elite boarding school founded in 1555; his mother, who dropped out of school at the age of 17 to join Bomber Command during World War II, raised the kids. His father died of cancer when Dyson was 9. After the loss, Dyson began pushing himself. He took up the bassoon despite hearing it was the most difficult instrument in the orchestra to learn. At 14, he started running competitively, often waking up at 6 am to train, sprinting up sand dunes (better for resistance training, he learnt). In the evening, he would typically run for another two hours until after midnight. It was the one thing that came easily to him in those days. “Suddenly I had something in which I could kick people’s asses occasionally,” writes Dyson in his 1997 autobiography.

A self-described poor student, he went to the Byam Shaw School of Art in London, where he met his wife, Deirdre. He later gained entrance to a graduate programme at the Royal College of Art even though he never completed his undergraduate degree. While in school, Dyson developed an offbeat design for an aluminum roof. That led to a meeting with Jeremy Fry, a well-regarded inventor who had installed a similar roof. The two hit it off, and Fry eventually offered Dyson his first full-time job at his manufacturing company, Rotork. Dyson helped design the company’s first sea trucks, essentially high-speed cargo boats, and peddled them to armies around the world, including Egypt’s, which used them to fight Israel during the 1973 Yom Kippur War.

When Dyson wasn’t at Rotork, he spent time fixing up his 300-year-old farmhouse near Bath. It was hauling cement during that renovation that inspired one of his earliest trademark build-a-better-mousetrap ideas: A modernised wheelbarrow. His version used a ball instead of a wheel because it distributed the weight more evenly and didn’t get stuck in mud.

In 1974, he quit his job and started making Ballbarrows with bank loans and help from his brother-in-law, who had recently inherited money. Two years later, with interest rates sky-high and debt of more than $270,000, they sold a 33 percent stake to an investor. In 1979, Dyson was forced out, in part because he wanted to extend the loans to fund more inventions while the others wanted to pay down the debt.

Still, that first startup gave Dyson a tremendous gift. Coloured powder sprayed on the Ballbarrows (even then he loved making his tools pop) collected on the factory equipment. Just before he was kicked out, he had an idea to suck up the annoying dust by installing a handmade industrial fan with a rapid spinning mechanism on the factory’s ceiling. Around the same time he was battling his family’s refurbished Hoover vacuum (he couldn’t afford a new one). It would give out as the bag filled up. On a Sunday in October 1978, after watching the movements of the factory’s cyclone-inspired contraption, Dyson rushed home and tore the bag off his vacuum. He replaced it with a cardboard version of what he’d made in the factory. It worked well enough to spur Dyson to try and create a mass-market version.

He and his mentor, Jeremy Fry, each put up $53,000 initially. And for the next five years, while he spent thousands of hours (and dollars) making those famous 5,127 prototypes, his artist wife kept the family afloat by selling illustrations to British Vogue and teaching still-life classes.

When it was finally done, in 1983, Dyson’s bagless vacuum was so powerful that its inner-cyclone mechanism separated air and dust at a speed of 924 mph and could pull cigarette smoke from the air. To pay off the debts, he decided to licence the technology. It took another two years to sign his first big customer. Apex, a Japanese company, agreed to pay him $78,000 upfront and a 10 percent royalty for the development of its $1,800 G-Force vacuum. Things didn’t go so well in the US, where initial licencing agreements unravelled and led to a tangle of lawsuits.

Image: Gareth Philips

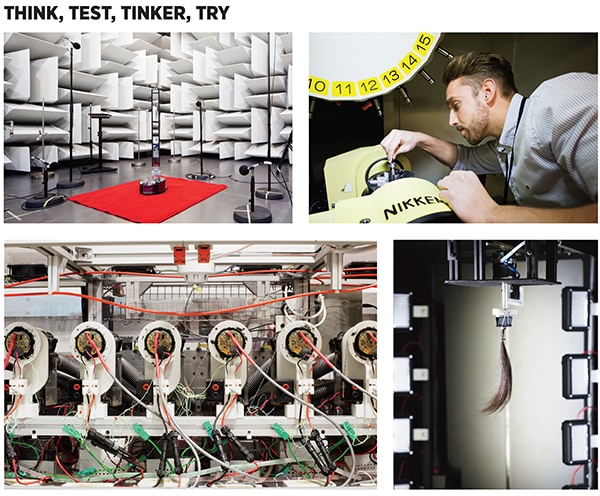

Inside Dyson’s labs, engineers try, try and try—a thousand times if necessary. Clockwise from top left: A chamber for acoustic testing to make sure the products are quiet; an engineer fiddles with a model of the impeller used in Dyson’s motors; human hair blown out by the Supersonic dryer is ready for inspection; the motor development team simultaneously tests 332 motors

Liberated from the nitty-gritty, Dyson refocussed on inventing. In 1998, he recruited five PhD students from the University of Kent and tasked them with building Dyson’s first robotic vacuum cleaner. Once again he spent years and went through 1,000 prototypes before he was satisfied. He scrapped the first model because of technology hurdles and high costs. “We’re never afraid to sort of take that step back and go, ‘It’s not right. We don’t launch it’,” says Mike Aldred, Dyson’s lead robotics engineer.

The quest for perfection might be Dyson’s biggest strength and his greatest weakness. iRobot beat Dyson to market by 14 years, introducing the first robotic vacuum cleaner in 2002. Last year, iRobot sold about 2 million of them, according to Euromonitor, for between $375 and $900. Dyson’s robotic vacuum, dubbed the 360 Eye, was finally unveiled in the US this past summer. Priced at $1,000, it combines 360-degree vision with a proprietary navigation system that helps it better manoeuvre around dining room chairs and under beds. The company refused to comment on how many it’s sold.

Dyson’s passion for invention is embodied in those yellow-and-black notebooks—each stamped ‘Confidential’—that his engineers carry around. In them they are expected to write down every idea they come up with, from how to smooth hair faster to ways to tweak the battery-operated vacuums. When the books are filled, they’re stored in a vault that engineers can access if they want information or ideas from a past entry. But crucially the journals are often used as the primary evidence for Dyson’s patent applications and frequent lawsuits. The company spends about $6.5 million a year on patent litigation. While many cases are settled out of court for undisclosed sums, it’s public knowledge that Hoover agreed to pay Dyson more than $6 million in 2002 for patent infringement of its cyclone technology.

And lest anyone dismiss Dyson as a dreamy-eyed tinkerer, it’s clear he knows how to play politics. The man who owns approximately 7,500 global patents was instrumental in getting the UK to revise its tax laws to favour patent holders. Dyson, whose holding company had been registered in Malta, a tax haven, penned a 2010 report, titled ‘Ingenious Britain’, at the behest of soon-to-be prime minister David Cameron on how to make the country a leading tech exporter. In it he supported the so-called ‘patent box’, which would reduce income taxes on patented products to 10 percent, and incentives for research and development. The patent box became effective in April 2013. One month earlier, Dyson had incorporated his holding company in the UK to take full advantage of the new laws. Since then the company’s taxes as a percentage of revenue have dropped by a fourth. “As a result we can reinvest more, so it’s helping us,” Dyson says.

Batteries have become something of an obsession for Dyson, who envisions a “huge number of product opportunities” that come from marrying better batteries with his products. To make his point, Dyson jumps up from his desk in Malmesbury, grabs a red-and-purple cordless vacuum cleaner from atop a couch and runs it along the floor to show how much easier it is than a standard plug-in. Battery-powered vacuums now make up two-thirds of the 9 million his firm sells annually. “It’s really taken over, and I think it will continue,” Dyson says. “But we need to have better battery technology.” Dyson’s wireless vacuums can run for only about 40 minutes before needing a recharge, which can take up to three-and-a-half hours.

That’s what led Dyson to pay $90 million to buy the promising battery startup Sakti3. The firm had developed, in a small lab setting, solid-state battery-cell prototypes that use a ceramic wafer on which stacks of film are deposited instead of the liquid electrolyte in conventional batteries, making them much safer. Solid-state can also store over 30 percent more energy for the same volume or over 50 percent more for the same mass, according to one of Sakti3’s patent applications, which means products could be smaller and lighter than they are with today’s most advanced liquid lithium-ion batteries. Sakti3 claims these batteries will last twice as long as anything else currently on the market and need far less time to recharge.

Dyson is one of several companies, including Toyota, Nissan and Bosch, that are betting on solid-state batteries to replace current rechargeable batteries, though many are focussed just on automotive applications. But if Dyson can scale up this battery production for use in household products, let alone cars down the road, it will be “groundbreaking,” says Daniel Abraham, a battery expert at Argonne National Laboratory in Illinois.

But Tesla’s high-profile founder, Elon Musk, who is spending billions to improve the current liquid lithium-ion batteries, doesn’t seem to agree. At a recent press conference, he said he’s not too worried about solid-state, at least when it comes to cars: “From when it works in the lab to when you actually get to high volume is at least four to five years. We don’t know of anything even in the lab that would be better than what we are doing here.”

Perhaps the biggest obstacle is the exorbitant cost. At the moment, it would cost at least $2,000 to make one solid-state battery to power a cordless vacuum, according to several battery experts. Dyson claims it can reduce these costs drastically and manufacture these batteries economically in the not-so-distant future. Others aren’t so sure. “We don’t see solid-state batteries being competitive for at least another decade,” says Chris Robinson, research associate at Lux Research, who tracks solid-state battery developments.

But don’t tell that to a true Dyson disciple. Says Bruce Brenner, Dyson’s director of energy-storage development, “We are spurred on by the impossible.”

(This story appears in the 30 November, -0001 issue of Forbes India. To visit our Archives, click here.)