How two young scientists built a $250 million business—out of waste

Houston-based Solugen is making cheaper, more effective industrial chemicals to help scrub everything from pools and hot tubs to oil and gas companies' wastewater. Up next: fertilizers

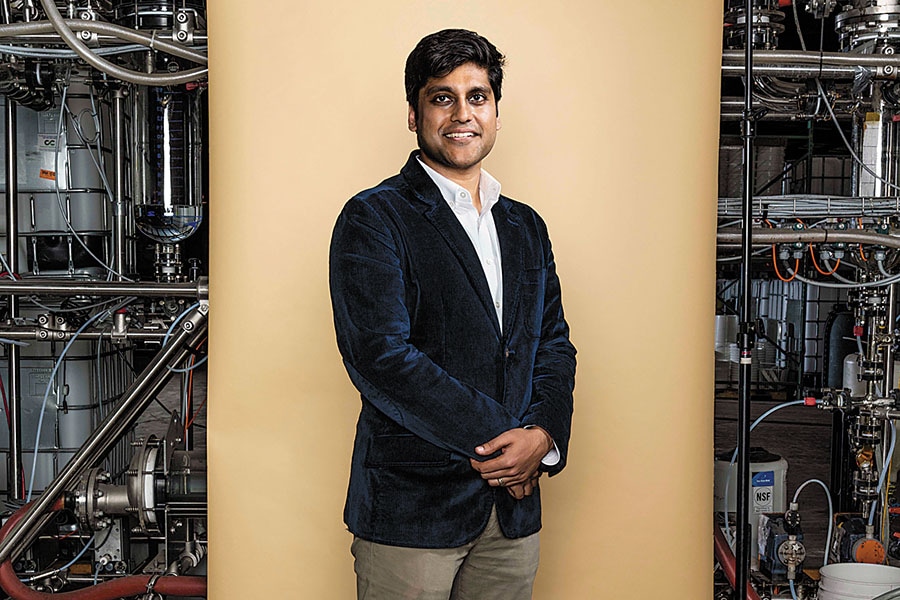

Solugen co-founder Gaurab Chakrabarti believes they have a cost-competitive replacement for fertilisers, which also biodegrades, which many chemicals in agriculture do not

Solugen co-founder Gaurab Chakrabarti believes they have a cost-competitive replacement for fertilisers, which also biodegrades, which many chemicals in agriculture do notImage: Phil Kline for Forbes

A long-standing poker game with a group of University of Texas Southwestern medical students in Dallas brought Gaurab Chakrabarti and Sean Hunt together. Wenly Ruan, Chakrabarti’s dissection lab partner and Hunt’s then-girlfriend (now wife), was the link. But soon Chakrabarti, an MD/PhD (or “Mud-Phud,” in medical school parlance) candidate researching a drug candidate for pancreatic cancer, and Hunt, a graduate student in chemical engineering at MIT, were geeking out over science.

“Sean was terrible at poker,” says Chakrabarti, now 31. Though Hunt kept losing, he continued to play for years, as he returned to Dallas from Boston to visit Ruan. And as they played, Chakrabarti and Hunt continued their geek-out. Chakrabarti was researching enzymes found in cancer cells that produce hydrogen peroxide, and he wondered if that process might apply to Hunt’s research on improving traditional chemical manufacturing. Hunt scoffed at the idea. “I was, like, ‘There’s no way an enzyme could be used in an industrial, long-scale chemical process’,” recalls Hunt, also 31. “But as we kept talking and diving into it, Gaurab convinced me.”

Six years later, in 2016, Chakrabarti and Hunt submitted their idea for a new business, which they called Solugen, to an MIT pitch competition. They won $10,000 as a finalist. Those funds allowed them to buy PVC pipes from Home Depot and pumps off eBay to build their first reactor system. They grew gene-edited yeast to produce the enzymes Chakrabarti had discovered—sort of like a craft brewery for the $2 trillion global industrial chemicals market—and then used those enzymes to make hydrogen peroxide. In this way, the Houston-based startup brought biology to the oil patch, combining their innovative bio-based peroxide with other bio-based chemicals for use in everything from spa cleaning to disinfecting wipes to wastewater treatments for oil-and-gas runoff.

Solugen’s revenue reached $12 million last year, largely from more than 30 mostly Texas-based energy and industrial customers (which it won’t name, citing competitive concerns) that use its wastewater treatment product. Chakrabarti and Hunt—alumni of the Forbes Under 30 class of 2017—expect revenue to surpass $30 million this year, though the company is not yet profitable as it spends heavily to expand.

Solugen raised $30 million in venture capital in April, and $68 million altogether, from Founders Fund, Valor Equity Partners and other investors, at a valuation of $250 million. Those numbers gained Solugen a spot on this year’s Forbes Next Billion-Dollar Startups list, one of 25 companies we think have the best shot of becoming unicorns. “I’ve seen so many pitches in my life, and I love it when I hear something I’ve never heard before,” says Founders Fund’s Brian Singerman, who first invested in the company in 2017.

Solugen has raised $68 million so far, and co-founder Sean Hunt expects revenue to surpass $30 million this year

Solugen has raised $68 million so far, and co-founder Sean Hunt expects revenue to surpass $30 million this yearImage: Phil Kline for Forbes

When they started, both Chakrabarti and Hunt were still finishing their PhD dissertations. Their original MacGyvered plant was big enough to produce just 19 liters of hydrogen peroxide a day. They marketed their first water treatment product, called PeroxyZen, for use in pools, hot tubs and spas after a group of float-spa owners contacted them on Facebook. Their sales pitch was that the product was petroleum-free, a boon for spas that like to market being “natural”. But what kept customers coming back was that the product worked better than traditional chemical cleaners. That was due to an interesting discovery they made early on: The enzymatic process that created the company’s bioperoxide also generated organic acids that cleaned out mineral build-up that can clog and corrode pipes over time.

The spa-cleaning business was a nice, niche operation, and in the early days they made the rounds to customers in their Subaru, dropping off 19-liter buckets of cleaning solution. But Chakrabarti and Hunt had bigger plans. In winter 2017, they joined the Y Combinator accelerator, one of the rare startups outside software to get in. Later that year, they signed a deal with wet-wipe manufacturer Diamond Wipes to launch a new bio-based brand called Ode to Clean. Diamond manufactured the wipes, while Solugen provided hydrogen peroxide and marketing. Because they’re made from plant starch, the wipes are biodegradable and don’t emit toxic fumes. Chakrabarti says they didn’t really care about the wipes per se, but figured the simple product would help Solugen sell to bigger industrial customers. “It was a Trojan horse for us, with an aim of selling the brand and getting a supplier contract,” he says.

Solugen’s first facility was built with PVC pipes from Home Depot and required manual operation; the newest iteration is automated

Solugen’s first facility was built with PVC pipes from Home Depot and required manual operation; the newest iteration is automatedImage: Phil Kline for Forbes

As in the Iliad, the plan worked. With the help of a salesman they hired from oilfield services giant Schlumberger in fall 2018, they were able to market wastewater cleaning products—that used the same chemicals as the spa cleaner—to oil drillers. “It sounds super-silly, but wipes got us into the industrials game,” says Chakrabarti. Solugen got out of the wipes business in summer 2018 when Diamond Wipes acquired Ode to Clean for less than $10 million; the company continues to get a small, but stable, piece of its revenue from supplying Diamond Wipes with hydrogen peroxide.

By September 2018, Solugen was doing so well that it needed a bigger space and, with a $19 million funding round in the works, had the cash to cover expansion. On the Loopnet commercial real estate site, Hunt scoured the Houston area for options. A half hour later, he was touring a decommissioned chemical manufacturing plant that had been used to turn oil into plastics, with Chakrabarti’s father, Gopendu, a chemical engineer and entrepreneur. The hulking factory, on a 5-acre site, still had intact piping and tanks, and even boasted a 1-acre apple and pear orchard, planted by the previous owner as a carbon offset. The elder Chakrabarti swore they’d never find a better space. After touring 20 more sites over the next month, Hunt finally agreed. Solugen paid nearly $3 million for the plant. It can currently produce about a tanker truck full of product (or some 15 kilolitres) per week, and Solugen is working to get capacity cranked up to multiple tanker trucks of product per day.

In its early days, Solugen’s co-founders carried 19-litre jugs to customers in their Subaru. Today, they produce enough for tanker trucks

In its early days, Solugen’s co-founders carried 19-litre jugs to customers in their Subaru. Today, they produce enough for tanker trucksImage: Phil Kline for Forbes

The size of the market for cleaning up wastewater is sizable, perhaps as big as $5 billion. The process for drilling for oil and gas is a dirty one, and generally yields large amounts of water contaminated with mineral scales. Regulators require this wastewater to be cleaned up before it’s repurposed for industry or agriculture. But this is a tough market, and Solugen faces competition from major chemical conglomerates in what has historically been largely a commodity business.

As with its spa cleaners, Solugen’s innovative use of enzymes in its wastewater treatment keeps mineral scales from building up on the water pipes while also preventing corrosion. In one case, Solugen tested its wastewater treatment with an oil and gas customer that had seen 20 percent reduced efficiency of its water injectors due to iron-scale buildup, a problem that cost it more than $29 million a year in lost revenue across the oilfield. The result: Production increased at the one well it was tested on without the need for additional acid stimulation treatments.

Unlike phosphates, such as hydroxyethylidene diphosphonic acid, or HEDP, there are also environmental advantages. The process of making 900 kilograms of Solugen’s wastewater treatment sequesters the equivalent of 1.2 metric tonnes of carbon dioxide, versus 2.7 tonnes emitted for HEDP, according to a report from Life Cycle Analysis. That’s an advantage for companies evaluated by governments and investors on environmental impact. The runoff from phosphate-based cleaners also causes algal blooms, harming local ecosystems and fisheries, a reason why the US and the EU have banned phosphates from consumer detergents.

Solugen can tout all those advantages as long as it can match the price of HEDP. “We go head to head with phosphates,” Hunt says. “We are not premium.” While the pandemic shuttered many manufacturing plants, Solugen’s operations in Texas were considered essential and remained open. Demand for its wastewater cleanup surged because of a reduction in fracking, which uses the contaminated water from oil drilling and does not require cleanup. The founders estimate demand for wastewater cleanup rose at least 50 percent since March, and they expect that to continue even if fracking resumes, because as oil drilling sites age, more water tends to be unearthed. Though low oil prices have led to hundreds of rigs being shut down over the past year, billions of gallons of water continue to require treatment every year.

During the pandemic, Solugen also began producing hand sanitiser by combining its hydrogen peroxide with alcohol from a local ethanol facility. The company produced more than 379 kiloliters, most of which it donated to local healthcare facilities facing shortages with the help of the non-profit group Operation USA. It plans to increase production of hand sanitiser to more than 3,700 kilolitres by year-end, and, with the product in high demand, is considering commercial opportunities.

These days, wastewater treatment accounts for some 80 percent of Solugen’s revenue, and Chakrabarti and Hunt see vast room for growth. To expand, Solugen is building a series of what Chakrabarti calls “mini-mills”, a term adopted from the steel industry that he uses to refer to small, localised production plants that can serve the needs of regional customers within a 320 km radius rather than requiring large-scale distribution. The first one, in Slaton, Texas, opened in 2019 and is now devoted entirely to hand sanitiser. A second one is planned for the Houston area. Each is located near an ethanol plant, from which Solugen can buy the corn waste it needs to power its biological production.

Next up, Chakrabarti and Hunt see potential in agriculture, an area where efforts to replace chemicals with biology have proliferated. The two believe that the same technology that allowed them to replace phosphate-based cleaners could also let them reinvent fertilisers by adding essential minerals and metals to soil. The fertiliser market, like the wastewater one, is enormous, at least $175 billion, and has long relied on chemical solutions despite their drawbacks.

“We believe we have a cost-competitive replacement, which also biodegrades where many chemicals in agriculture do not,” Chakrabarti says. He expects regulatory approval soon from the US Environmental Protection Agency, pending the results of tests in Australia, South America and the US, that would allow Solugen to begin selling the product by the end of the year. Thanks to all this, Chakrabarti and Hunt are confident enough in expansion that they’re planning to add at least 20 employees to Solugen’s now 70-person workforce by mid-2021.

Longer term, the pair figure on continuing to investigate the workings of enzymes made by various cancers, and engineering ones that have evolved to be particularly good at making valuable products. “It’s like the early days of software development,” Hunt says. They are investigating a dozen or so enzymes now, each of which could make a different target chemical in tandem with biologically produced hydrogen peroxide. That success, Hunt figures, makes losing all those poker games worthwhile. “It’s been quite a wild ride,” he says. “Nobody thought poker would lead to this, that’s for sure.”

● With additional reporting by Christopher Helman.

(This story appears in the 30 November, -0001 issue of Forbes India. To visit our Archives, click here.)